CN Filler Rubber is a black, premium grade, thin rubber sheet with CN bonding layers on both sides, it is designed for use in repairing conveyor belts or bonding rubber to steel surfaces. it features a self-extinguishing, antistatic, and moderately oil-resistant formulation, with CN layers on both sides for maximum adhesion. it is ideal for repair of longitudinal breaches, damaged top coating, and damaged edges of conveyor belts of all types including those reinforced with metal and aramid cord, and also for finishing of splice during pulley lagging.

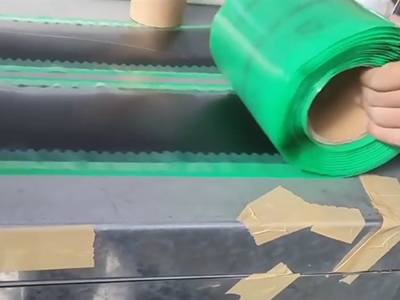

CN Filler Rubber

Description

CN filler rubber both-sides CN Layer is to achieve ultimate adhesion when bonded to steel or other rubber surfaces. CN filler rubber is excellent for any damage when carrying out a cold repair on a conveyor belt. It is also used as backing layer on polyurethane lining systems.

Technical Specifications:

Polymer: NR/SBR

Density: 1.12-1.2g/cm3

Hardness:60 +- 5 shore A

Color: Black Body with Green CN Bonding both sides

Sizes:

1. Standard Roll Sizes: 500mmx10m rolls

2. Thickness: 1.5mm, 2mm, 3mm etc

Features

Both Sides CN Bonding Layers – Ensures strong adhesion to rubber surfaces, ideal for conveyor belt repairs.

High Elasticity and Durability – Resists wear, impacts, and longitudinal cracks while maintaining flexibility.

Versatile Applications – Repairs top layers, sidewalls, and seams on all conveyor belt types (including steel cord & reinforced conveyor belts).

On-Site Efficiency – Enables repairs without disassembling the conveyor system, minimizing downtime.

Drum Lining Compatibility – Suitable for finishing touches during pulley drum lining.

Application

Quarries and Mines – Quick repairs for damaged conveyor belts in harsh conditions.

Conveyor Manufacturers and Vulcanizers – Cost-effective cold bonding solution.

Steel/Rubber Bonding – Secure adhesion even in severe environments