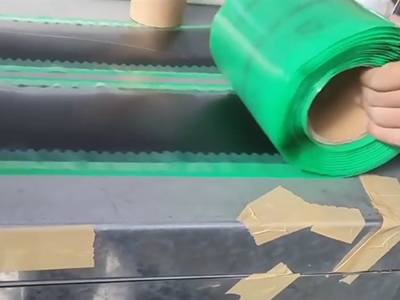

Fabric Reinforced Repair Strip(repair band) is made by a neoprene-based CN bonding layer on one side and NR & SBR, etc. rubber compound on the other. It is reinforced with a fabric layer to increase tear strength and puncture resistance. Our Fabric Reinforced Repair Strips CN layer Adhesive Force reaches about 9N/mm after 72 hours of bonding. It is a reliable repair materials for your conveyor belt repair.

Fabric Reinforced Repair Strip

Description

| Item | Description | Size ( thick*W*L) mm |

| 1 | Standard repair strip | 2.2*100*10000 |

| 2 | Standard repair strip | 3.2*150*10000 |

| 3 | Standard repair strip | 3.2*220*10000 |

| 4 | Standard repair strip | 3.2*220*10000 |

| 5 | Standard repair strip | 3.2*220*10000 |

| 6 | Fabric reinforced strip | 3.6*100*10000 |

| 7 | Fabric reinforced strip | 4.6*150*10000 |

| 8 | Fabric reinforced strip | 4.6*220*10000 |

| 9 | Fabric reinforced strip | 4.8*300*10000 |

| 10 | Fabric reinforced strip | 4.8*400*1000 |

Customized Sizes available

Application

Fabric Reinforced Repair Strip( band )is mainly used for the repair of damage to conveyor belt ply and covers or steel cord conveyors in heavy operating conditions or applications, which require maximum tear strength and puncture resistance;

Fabric reinforced repair strips with bonding layer for cold repair and joining of conveyor belts. BL layer with beveled/waved edge to allow repair stripes(bands) to completely merge with the existing conveyor belt cover.

Both two kinds of Standard & Fabric Reinforced Repair Strips used for conveyor system applications in the Mining, Quarrying, and Mineral and Metals processing industries but used on conveyor belts in any application where required.

They are also used for the reinforcing of rubber joins in impact curtains, transfer sleeves or loading socks or any application where the rubber is bonded together or repaired.

Package

each roll in a carton, all cartons in a plywood case.